Traditional olive oil production

In order to produce quality olive oil, it is essential to respect ancestral production methods. These methods are passed down from generation to generation in the greatest secrecy.

This is why, at Oliviers&Co. we appreciate the craftsmanship of our producers. They have an undeniable know-how that allows them to extract the best from the olive tree: the green gold, exclusively by mechanical pressing of the olives.

To obtain a grand cru, several conditions must be met:

- A land renowned for the production of its olive oil

- Well-irrigated orchards exposed to the Mediterranean sun

- Olive trees maintained and treated using traditional methods

- Storage and packaging of the olive oil in optimal conditions

Olive oil production is modernised for the consumer

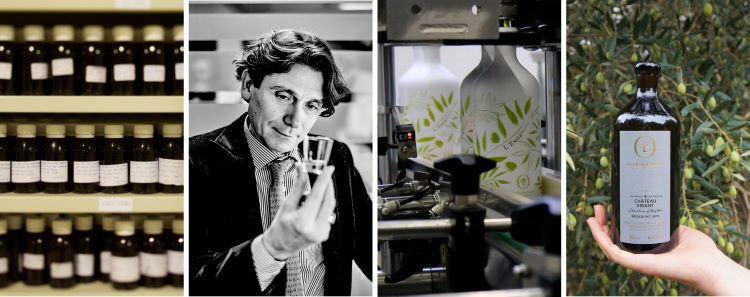

While Oliviers&Co. considers traditional know-how to be of paramount importance in the production of high quality olive oil, we also place great emphasis on modernity. Indeed, we consider it essential for the consumer that strict controls are carried out to guarantee the quality of our extra virgin olive oil.

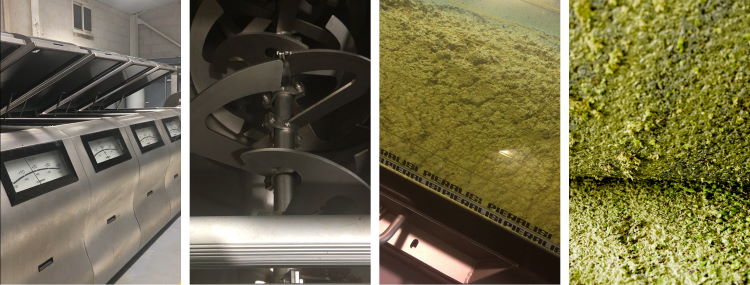

Today's mills are becoming more modern and automated, but the ones we work with remain entirely mechanical, in order to carry out all the stages of the traditional pressing process and to guarantee a high quality oil, preserving all its olfactory, gustatory and nutritional properties.

The stages: from the orchard to the bottle

To know everything about the stage before production: discover the olives harvest.

-

The olives are set in the orchard, fall onto large nets, are picked up and then put into crates to be transported in the truck's trailer.

-

The same day, on arrival at the mill, often located right next door, they await their turn to go through all the stages of processing. All the olives from the producers we work with at Oliviers & Co are pressed on the day of the harvest to guarantee optimal freshness of the oil.

- The olives are transferred to a conveyor belt for de-leafing: branches and leaves are separated from the olives. The olives are washed and retrimmed one last time to remove the remaining leaves.

- The olives are crushed: the flesh and stone are pulverised to form an olive paste, which is transferred to a tank for mixing. The mixing of the olive paste is very important because it allows the optimization of the mixture between the 3 elements: oil, water and solid residue that are formed during the crushing. Kneading is very controlled because the physical movement must not cause the paste to overheat: each olive or mixture of olives requires a certain amount of kneading time and an optimal kneading temperature to produce the best possible oil.

-

The pulp then passes into the decanter: this is the central stage of any mill: the centrifugal force allows the three components of the pulp to be separated:

- the solid residue, the heaviest, is sent to the periphery of the decanter and evacuated

- the lighter oil remains in the centre and is sent to the filter

- the water between the two is evacuated

-

The fresh olive oil is ready and will be stored in a tank.

-

Oliviers & Co selects each year, following the harvest, batches of olive oil from its partner producers, according to very strict specifications. The selected vats are then sent to our factory located in Mane in Haute-Provence for bottling or canning.